Interview: Real-time applications for motion and robotics with virtual controllers

Real-time applications for motion and robotics with virtual controllers

August 29, 2025

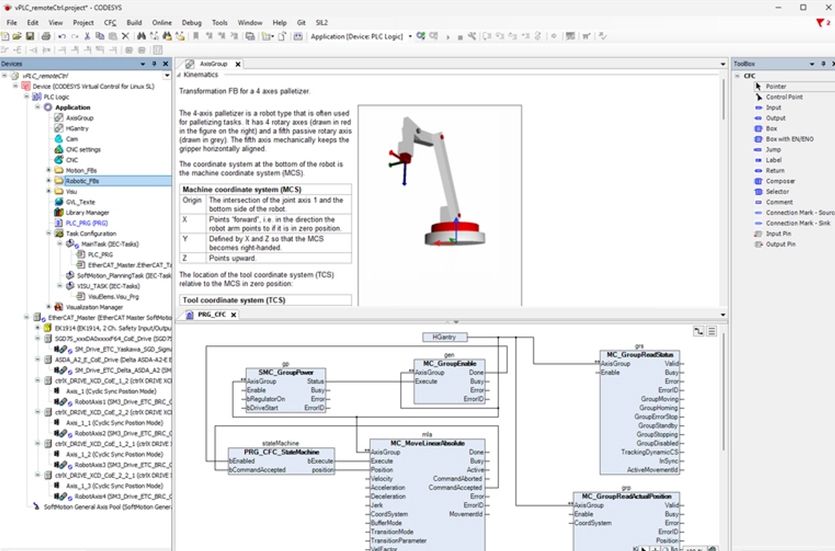

Automation with virtual controllers promises considerable savings potential in terms of procurement, maintenance and operation compared to conventional control technology. But what about applications in which, for example, coordinated movements place high demands on real-time behavior? If a suitable protocol is used for industrial communication or if modern fiber optic cables are used as the transmission medium, virtual control technology can also score points, as the fourth part on virtual control systems shows.

The first applications with virtual controllers are now in productive operation: hosted on IT servers, they are replacing physical PLCs in Audi AG's production lines, for example. A major advantage of virtual controllers is that they are much easier to maintain (see articles on the development (Part 1) and use (Part 2) of virtual controllers). Security updates can also be rolled out much more quickly and comprehensively in order to harden production systems against targeted or random attacks. And because virtual safety controllers such as Codesys Virtual Safe Control SL are now also available with IEC 61508 certification for SIL3 applications (see article Safety (Part 3)), there are no longer any restrictions on their use.

Read more at www.kem.industrie.de » (German language)